For dosing powders, pellets, flakes and fibers in a wide variety of processes, there is a wide choice of diverse types of dosing screws. The challenge remains in selecting the most appropriate dosing screw for a specific application.

Selecting the right dosing screw

We base the choice of the most appropriate dosing screw on three variables:

– shape of the bulk material and particle size

– bulk material characteristics

– desired dosing capacity

Below is an overview of the main types of dosing screws.

In addition, a selection chart is available for download here on the page to help select the most suitable type of dosing screw in combination with the character of the bulk material. The selection chart focuses exclusively on dosing screws. Other types of dosing such as, for example, vibratorytray feeders or weighbelt feeders are not considered here.

Of course, you can always contact SPS | Solids Process Solutions for more information and advice.”

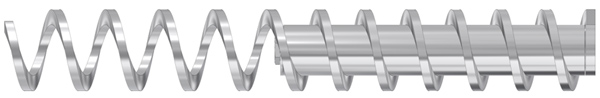

SINGLE-SPIRAL SCREW

Basically, an open spiral lends itself well to dosing many types of bulk material. Chamfering the spiral profile on the outside full length backward greatly reduces turning resistance and reduces the chance of fouling.

For above-average space between dosing trough and screw, pins at the screw circumference increase access to the screw, resulting in a higher and more consistent screw filling rate.

For rigid bulk materials that provide high resistance, a shaft in the core strengthens the screw and reduces screw output, depending on the shaft diameter.

A second spiral, shifted 180°, smooths out a pulsating dosing at low speeds.

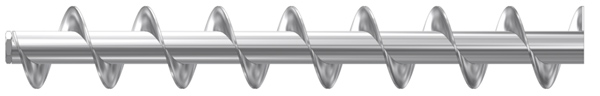

SINGLE-BLADE SCREW

Blade screws are also well suited for many types of bulk materials. However, they combine more robustness with lower metering capacity due to the presence of a shaft. In addition, there is more opportunity for bulk material buildup due to the larger contact surface.

Use of a blade screw is a good solution for flushing bulk material due to the braking effect of the closed blade. A version with a double blade at the end provides an additional braking effect.

For slightly flushing bulk material that flows poorly after deairation, a progressive pitch is recommended.

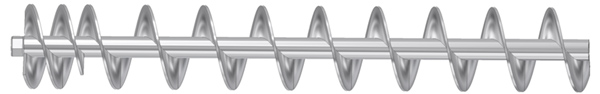

FIBER SCREW

Dosing reasonably to well flowing, bonded glass fibers up to about 6 mm in length gives the best results with a blade screw executed with a tapered core in the trough transitioning into an open blade.

UNBOUND FIBER SCREW

Serrations in the screw blade ensure that when dosing chopped, entangled fibers with varying fiber lengths, the bulk material is forced along by the screw. A staggered pitch and shaftless zone in the dosing tube give the bulk material sufficient space to minimize displacement.

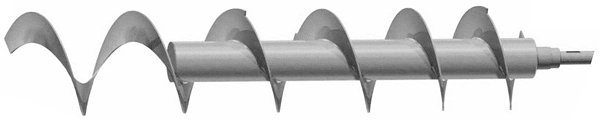

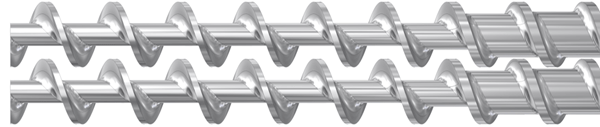

TWIN-SCREWS

When a single-screw is no longer sufficient, twin-screws can provide a solution. This may occur with adhesive powders that lead to clogging in a single-screw or with extremely flushing bulk materials for additional inhibition.

TWIN-CONCAVE SCREWS

Concave screws move bulk material through the outer sides while cleaning each other in the middle zone where the screw profile interlocks. In this way, adhesive powders can be dispensed and product build-up is immediately removed. The saw-tooth profile of the screws acts as a brake on flushing bulk material.

Should the need for double-screw dosing eventually arise, you can choose to dose pellets in addition to powders. To do this, just change the concave screws for double blade screws or double spiral screws.

Download the selection card for dosing screws below

The selection card focuses exclusively on dosing screws. Other types of dosing, such as vibrating chute dosing and dosing belt weighers, have not been taken into account here.

You can always contact SPS Solutions for more information and advice.