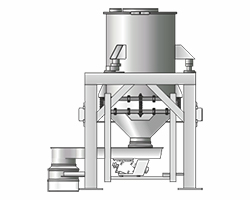

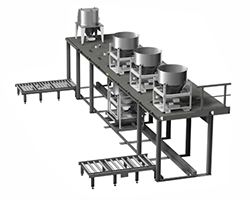

Accurate filling of reactors with powders and pellets according to recipe.

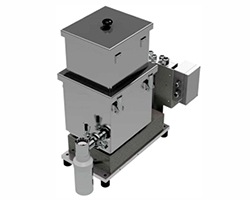

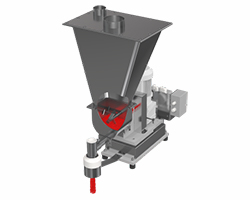

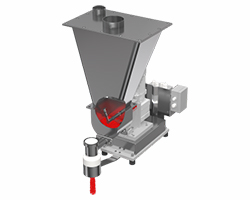

Accurate filling of reactors with powders and pellets according to recipe, aggressive, toxic or dusty in dry conditions to your prevailing positive airflow or inert gas injection. Brabender Technologie doses efficiently, economically, enables continuous recipe documentation and creates humane, ergonomic working conditions for the operator.

The self-cleaning JetFilters of Brabender ensure a dust-free deaeration. The feeders are available for various explosive conditions according to ATEX. Refill systems for the gravimetric dosing units ensure further optimization.

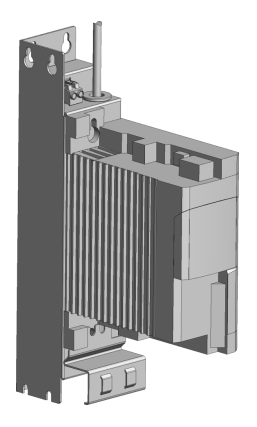

A continuous and reproducible process is of most important in the production of powder coating. Therefore, high precision is required from the extruder screw elements in order to provide excellent self-cleaning properties. To keep the process temperature low, Extruder Experts offers special segments and screw configurations.

Would you like more information about a product for this industry? Please ask, we will answer.