Grain, milk powder, sugar, lactose, starch, pasta, spices, flavours

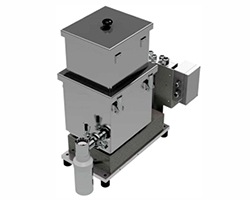

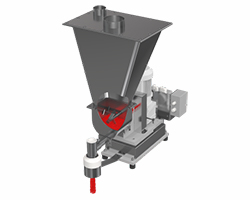

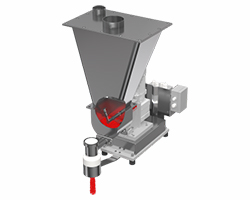

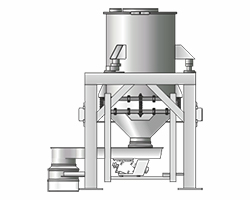

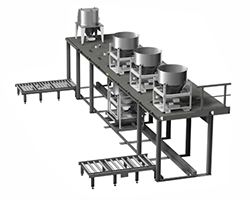

Brabender Technologie gravimetric feeders for integration in tracking and tracing systems provide accurate, reproducible and contamination free dosing, continuous or discontinuous. Grain, milk powder, sugar, lactose, starch, cocoa and additives for cereals, pasta, spices, flavours. The Brabender Food Grade Feeders are designed in accordance with the applicable relevant hygienic standards and guidelines (DIN EN 1672-2, EHEDG, FDA, etc.).

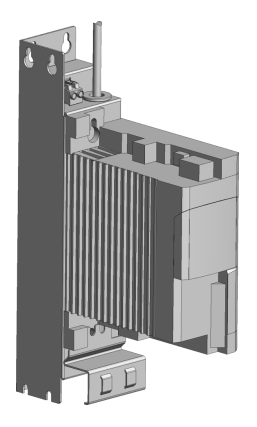

Available in execution for various explosive conditions according to ATEX. Accurate, efficient and dust-free. Self-cleaning JetFilters from Brabender provide hygienic and dust-free venting.

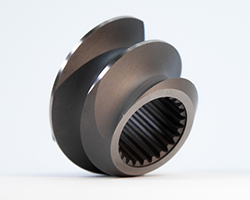

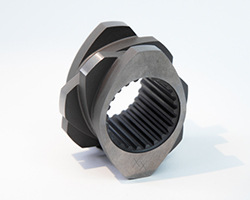

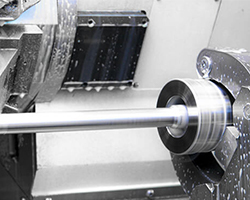

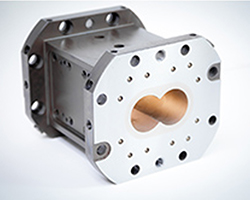

All extruder parts of Extruders Experts guarantee a careful use of your raw materials. With this the highest product quality and production efficiency can be achieved. The extruder parts of Extruder Experts optimize your extruder performance when using Coperion, Clextral, Baker Perkins and Bühler extruders amongst others.

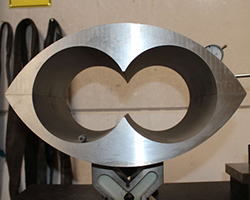

Extrusion of cereals requires specific know-how. Raw materials varying in quality and properties are processed into one product with a good expansion and texture. Constant quality must be guaranteed at high throughput speeds. Good product input and fast energy supply, e.g. with steam injections, good self-cleaning of the extruder screws are just as important as easy cleaning and good corrosion resistance.

Production of modified starch is all about the poor flow properties. With an optimal capacity of the extruder screw, a good throughput can be achieved. Mixing and dispersing requires very sensitive kneading to open the starches. Extruder Experts has experience with those extruder processes.

Would you like more information about a product for this industry? Please ask, we will answer.