Granules, pellets, powders, fibres, flakes or liquids.

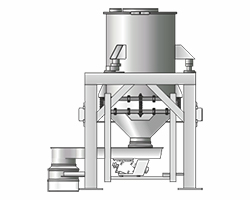

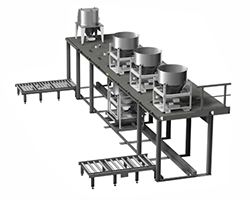

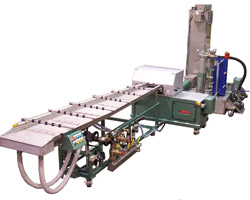

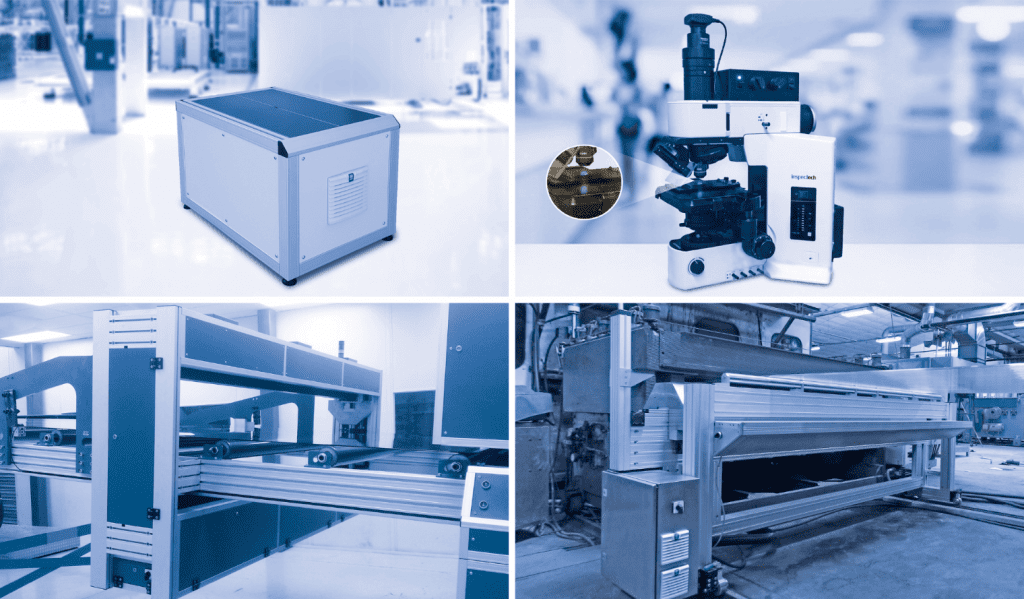

Dosing by recipe of various components to extruders. Granules, pellets, powders, fibres, flakes or liquids. From fillers, enhancers, flame retardants, impact modifiers to UV stabilizer. The Brabender Technologie feeders are quick and easy to clean for quick change over. Single or twinscrew, vibrating tray or weighbelt, volumetric or gravimetric, Loss-In-Weight or flow measurement for solids or liquids. Controlled by the famous Congrav feeder controllers Brabender creates high precision dosing solutions. Available for various explosive conditions according to ATEX. Refill systems for the gravimetric dosing units ensure further optimization.

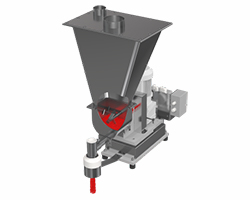

Production of masterbatch involves more and more different, individual colors, highly concentrated. Without dead zones in the extruder screw and easy efficient cleaning reduces downtime and increases product quality. All this is not easy, but certainly achievable!

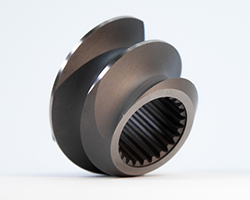

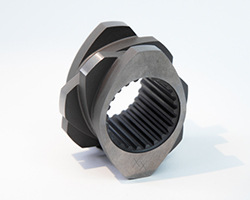

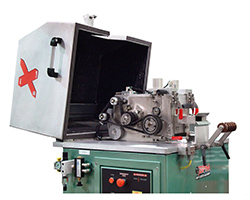

Even very difficult to disperse colorants can be absorbed homogeneously by using special extruder elements of Extruder Experts.

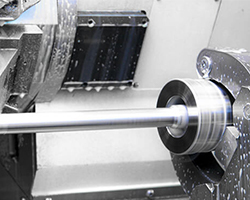

Each compounding process requires knowhow about all important conditions. Extruder Experts offers the right components for your process to perfectly meet your requirements. Many different compounding processes have already been successfully optimized by Extruder Experts.

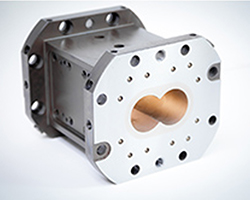

Production of engineering plastics is the top class of standard applications. High filled and abrasive by glass or carbon fiber, friction sensitive by additives, when processing at the highest temperatures and even extra corrosive degradation by fluor or bromine. A well-known and experienced field for Extruder Experts. Together with you, Extruder Experts will find the right configuration and suitable alloys for the processing section of your extruder.

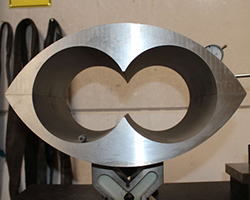

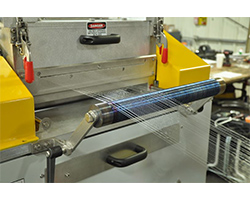

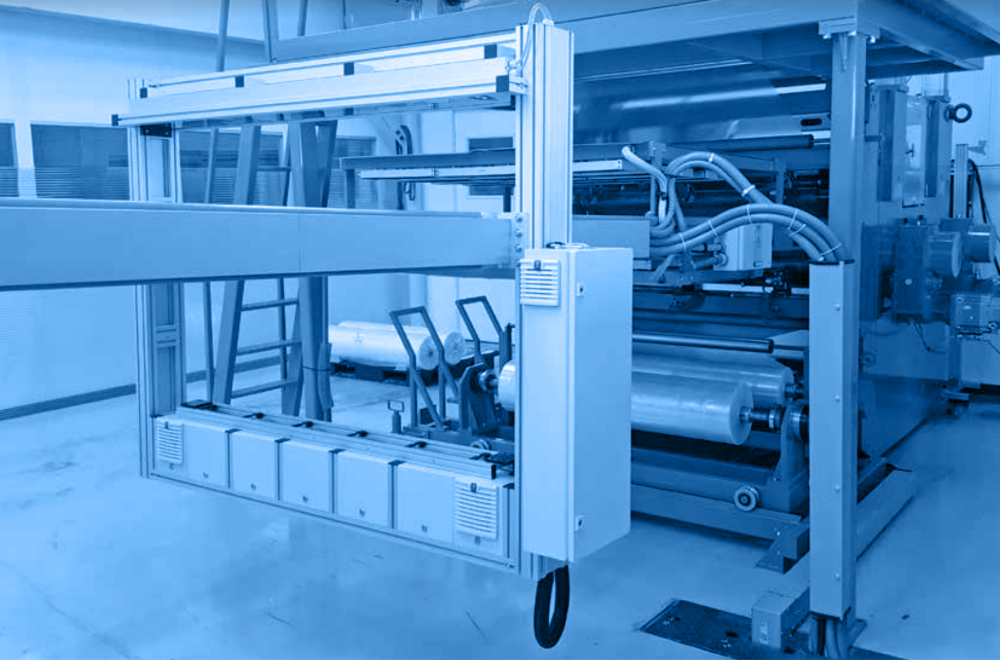

ECON’s innovative technology enables the granulation of plastics that are impossible with conventional techniques. The patented diehead in combination with the underwater pelletizer allows processing of plastics at high temperature and high fill rate. Even plastics with a high MFI can be pelletized (PP to MFI 2400). Processing viscous products (such as elastomers, natural resins, silicones or hot melt) also gives excellent results. In addition to difficult materials such as Liquid Crystal Polymer (LCP), ECON can also produce micro pellets.

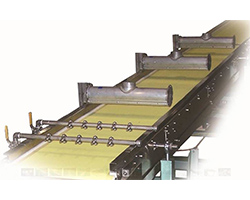

Pelletizers from Bay Plastics Machinery pelletize the strands from the extruder into pellets. For a variety of thermoplastics including glass fibre reinforced and highly filled thermoplastics, complete manual and automatic granulation systems, cooling baths, strand dewaterinhg and drying systems.

Would you like more information about a product for this industry? Please ask, we will answer.