Brands

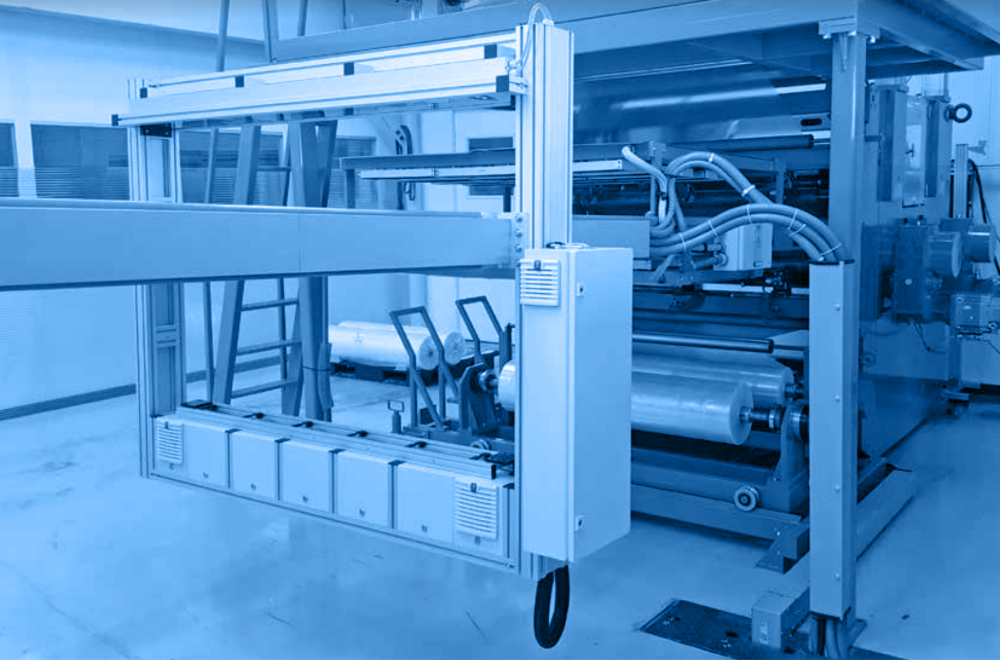

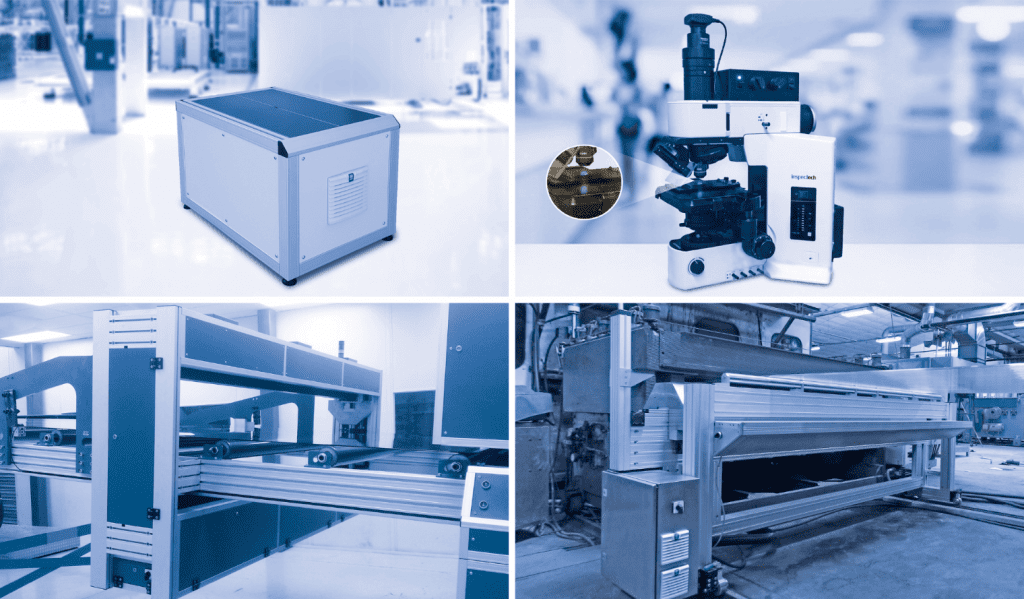

You want to be able to guarantee the quality of your pellets; you want to be able to detect deviations in pellets such as black specks, tails, shape, size and shift of colour. For the plastic compounding-, masterbatch- and recycling industry Inspection Technologies offer inline inspection solutions. The systems are small in size, without drive, conveyor belt or vibrating tray. Easy to integrate in your process line, easy to operate, quick to clean and with an affordable price. Possibilities to make adjustments so that the system meets the specifications and requirements for each process line. User-friendly, convenient and effective user interface allows criteria to be set for warning and disqualification by combining histograms and thumbnails of pellets.

• Leading specialist in visual systems for quality control since 1973.

• Detection of visible impurities in pellets.

• Pellet contour analysis – detection of “tails” caused by impure cutting

• Pellet size monitoring – median variation in pellet size and detection of off-spec pellets

• Detection of colour variation

• Without use of drive, conveyor belt or vibratingtray.

• Easy installation and integration into your process line.

• Quick and easy cleaning and set-up.

• Easy to make adjustments to meet the specifications and requirements for your process line.

• Warning and disqualification criteria easily adjustable via user-friendly interface.