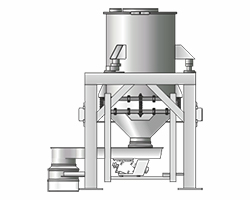

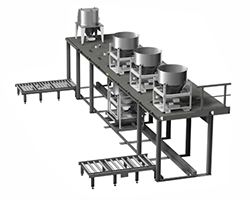

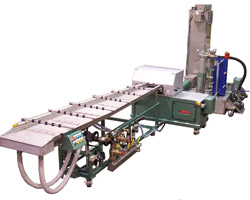

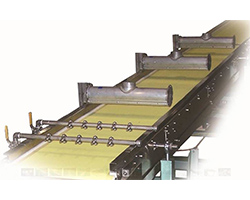

Reprocessing of feed, food or plastics. Dosing of crushed or grinded components and additives.

Reprocessing of feed, food or plastics. Dosing of crushed or grinded components and additives. Pellets, fibres, chips or powders.

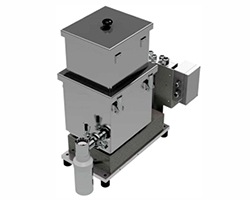

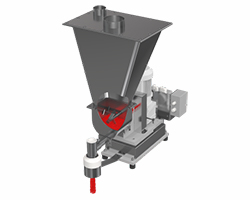

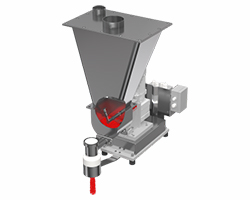

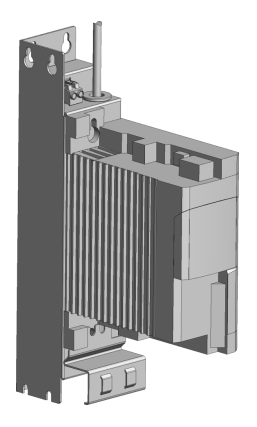

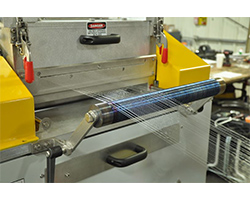

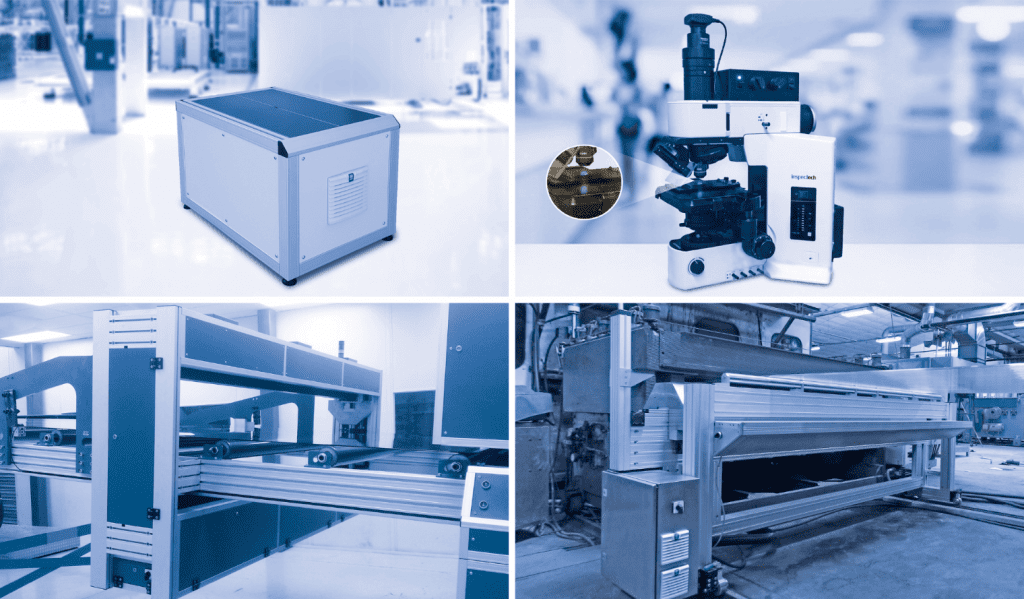

Brabender Technologie’s standard delivery program provides the various types of feeders; single or twinscrew, vibratingtray or weighbelt, volumetric or gravimetric, Loss-In-Weight or flow measurement for solids or liquids. With the application of Brabender gravimetric feeders, integration with tracking and tracing systems is very feasible. The self-cleaning JetFilters of Brabender provide a low dust deaeration according to the strictest emission guidelines.

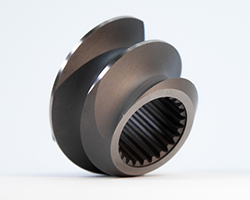

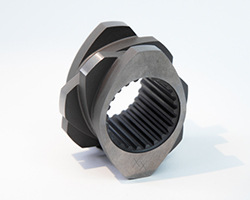

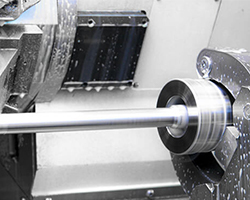

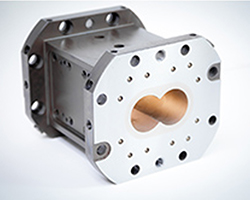

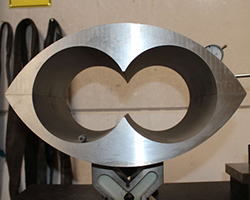

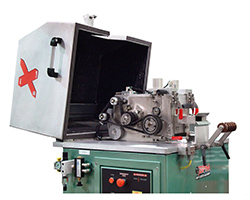

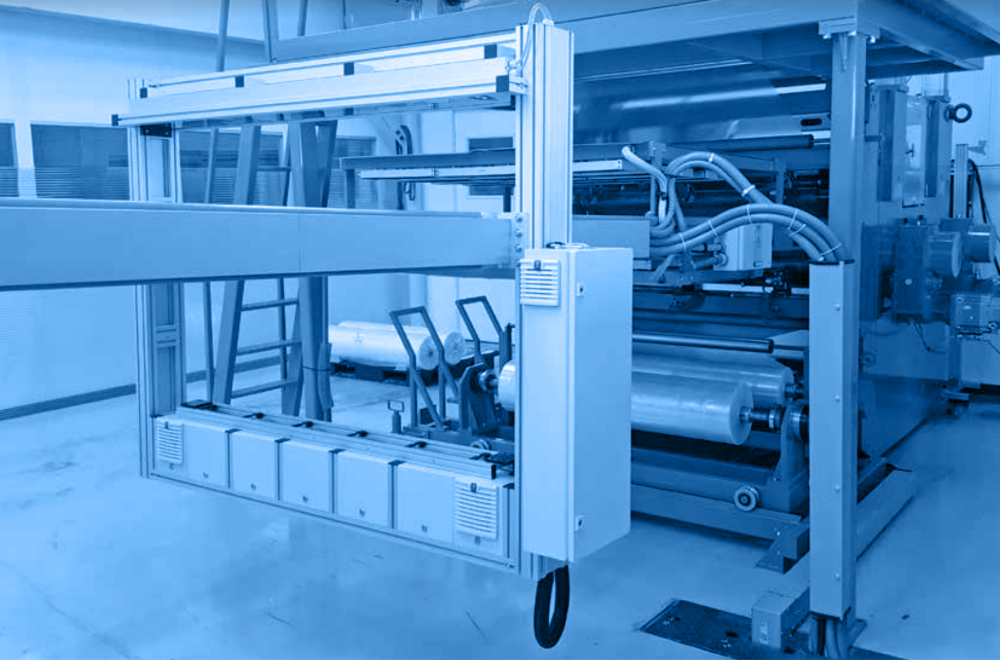

Robust parts of the extruder from Extruder Experts for the best price-performance ratio. This is the key for this application. Recycling of plastic raw material is always contaminated with non-plastic parts, the dosing of flakes, chips and powder-like materials is never easy. Also the screw configuration should work for many different recycling tasks.

Would you like more information about a product for this industry? Please ask, we will answer.