In many production environments within the food industry, large quantities of ingredients such as powders, pellets, flakes and fibers are dosed daily. Yet SPS | Solids Process Solutions regularly observes that suboptimal choices are made when selecting dosing screws.

The consequences can be considerable: disruptions in the dosing process, irregular supply of raw materials, unnecessary downtime or even rejection of batches due to inaccurate dosing. In many cases, the root cause is an incorrectly selected dosing screw – one that is not properly matched to the bulk material and process requirements.

Support in making the right selection

To assist engineers, production managers and process technologists in the food industry in making the right choice, SPS | Solids Process Solutions offers two valuable tools:

📄 Download here:

- Dosing screw selection chart (PDF): helps identify the appropriate dosing screw type based on bulk material characteristics.

- Bulk material characteristics overview (PDF): includes practical examples of food ingredients and their flow behavior.

These tools are based on many years of experience and provide a quick overview of suitable dosing solutions.

💬 Do you have specific questions or are you facing challenges in your dosing process? Feel free to contact us – entirely without obligation – for a personal consultation. Our specialists will gladly advise you, including on alternative dosing techniques, such as vibratory tray feeders, weighbelt feeders or custom transport systems.

SPS | Solids Process Solutions is your partner for practical and well-considered solutions for reliable dosing in the food industry.

How to select the right dosing screw?

For dosing powders, pellets, flakes and fibers in a wide variety of processes, there is a wide choice of diverse types of dosing screws. The challenge remains in selecting the most appropriate dosing screw for a specific application.

We base the choice of the most appropriate dosing screw on three variables:

– shape of the bulk material and particle size

– bulk material characteristics

– desired dosing capacity

Below is an overview of the main types of dosing screws.

In addition, a selection chart is available for download here on the page to help select the most suitable type of dosing screw in combination with the character of the bulk material. The selection chart focuses exclusively on dosing screws. Other types of dosing such as, for example, vibratory tray feeders or weighbelt feeders are not considered here.

Of course, you can always contact SPS | Solids Process Solutions for more information and advice.

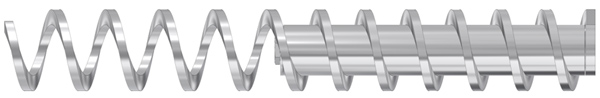

SINGLE-SPIRAL SCREW

Basically, an open spiral lends itself well to dosing many types of bulk material such as wheat flour, carrot powder, apple powder, icing sugar or citric acid powder. It also works well for coarser ingredients like (hazel)nuts, peanuts, rice crisps, or chopped dried vegetables or fruits.

Beveling the spiral profile on the outside full length backward greatly reduces turning resistance and reduces the chance of fouling as for instance with vanilla powder, ground nuts, almond powder, potato starch, corn starch, flour or raisins.

For oversized space between dosing trough and screw, pins at the screw circumference increase access to the screw, resulting in a higher and more consistent screw filling rate. This is applicable when using a significantly smaller screw diameter than the trough size to achieve lower dosing capacity.

For rigid bulk materials that provide high resistance, like some types of potato starch, a shaft in the core strengthens the screw and reduces screw output, depending on the shaft diameter.

A second spiral, shifted 180°, smooths out a pulsating dosing at low speeds.

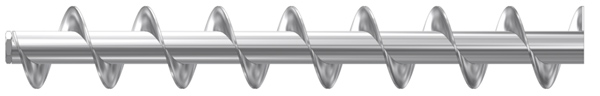

SINGLE-BLADE SCREW

Blade screws are also well suited for many types of bulk materials. However, they combine more robustness with lower metering capacity due to the presence of a shaft. In addition, there is more risk of bulk material build-up due to the larger contact surface.

Use of a blade screw is a good solution for flushing bulk material due to the inhibiting effect of the closed blade. Examples include flowing agents. A version with a double blade at the end provides an additional braking effect.

For slightly flushing bulk material that flows poorly after deairation, a progressive pitch is recommended.

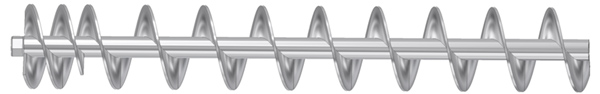

FIBER SCREW

Dosing reasonably to well flowing bonded fibers – such as dried dill or thyme – gives the best results with a blade screw executed with a tapered core in the trough transitioning into an open blade.

UNBOUND FIBER SCREW

Serrations in the screw blade ensure that when dosing chopped, entangled fibers with varying fiber lengths, the bulk material is forced along by the screw. Coconut fiber is a good example, but other fibrous herbs also apply. A staggered pitch and shaftless zone in the dosing tube give the bulk material sufficient space to minimize displacement and clogging.

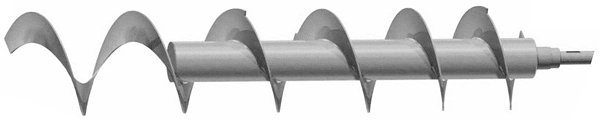

TWIN-SCREWS

When a single-screw is no longer sufficient, twin-screws can provide a solution. This may occur with adhesive powders, such as certain flowing agents or nut powders, or with extremely flushing bulk materials requiring additional inhibition.

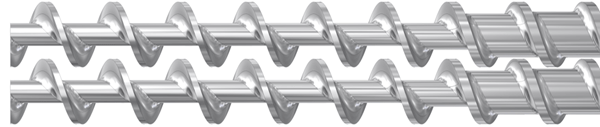

TWIN-CONCAVE SCREWS

Concave screws move bulk material through the outer sides while cleaning each other in the middle zone where the screw profile interlocks. In this way, adhesive powders can be dispensed and product build-up is immediately removed. The saw-tooth profile of the screws acts as a brake on flushing bulk material.

Should the need for double-screw dosing eventually arise, you can choose to dose pellets in addition to powders. To do this, just change the concave screws for double blade screws or double spiral screws.

Download the valuable tools for the food industry for free below

The selection chart focuses exclusively on dosing screws. Other types of dosing, such as vibratory tray feeders or weighbelt feeders, are not considered here.

The bulk material characteristics food overview contains practical examples of food ingredients and their behavior as bulk material.

Of course, you can always contact SPS | Solids Process Solutions for more information and advice.